Viscose

Approximately 7 million tons / 7% (7%) of the world’s textile fiber production is viscose fibers made from wood cellulose. The proportion is expected to increase sharply due to the usability and environmental values of cellulose. The total production of fibers has been estimated to reach at least 150 million t / a by 2050, when higher demand, even with a share of more than 10%, will be focused on cellulose-based materials.

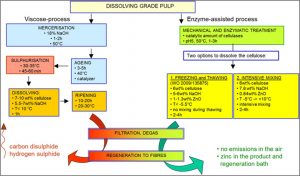

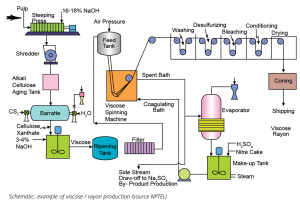

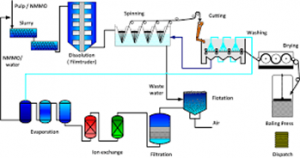

Under the pressure of technological and environmental requirements, the viscose process has become more productive and may currently be a Biorefinery where all fractions of production are utilized (Figure 1). Sustainability reports and audits (including Canopy) most often achieve a carbon-positive result. In addition to factors of production, the importance of the origin of forest-based pulp raw material is crucial. It is audited using international forest sustainability standards, FSC and PEFC. It is particularly advantageous when the fiber production is integrated to pulp mill in connection with the production of dissolving pulp, which reduces the costs in the production chain. Additional to the fiber production the integration is connected to the utilization of side streams for manufacturing of acetic acid, furfural, lignosulphonate, xylose and fine chemicals.

Figure 1. Schematic presentation of viscose process

The size of the profitable production unit for viscose fibers – the production line – has increased from the level of 15 kt/a in 1985 to more than 3 times, such as 50 kt/a, according to investments in 2020. Due to the slow spinning speed, the number and size of spinnerets has been growing (Fig. 2., Fig. 3), which makes the process control of higher importance. If 20 of the current 50 largest mills realizes three additional investments in this size category over 30 years, according to novel estimates the production of viscose fibers would increase by 3 mill.t/a up to 11 million annual tonnes. In addition, there will be upgrades to existing smaller production lines, which will generally increase capacity. With a capacity increase of about 35%, the renewal of about 350 production lines would have an impact of 1.4 mill.t/a. Depreciation of the process machinery (10% / year) is calculated for a relatively short period of time (5-10 years), so the total impact could be more than 4 million t/a by 2050. Using capacity enlargements and technology up-gradings, the total production of viscose fibers could reach 12 mill.t/a.

Figure 2. The detailed photo of spinning viscose

Figure 3. The structure of a viscose fiber tow. spinneret head consisting of 25000 holes (51 μm)

The production line is a unit that can be duplicated / enlarged on demand in an existing factory area, while at the same time expanding the production of viscose solution. The new production lines utilize 99% of carbon disulphide by recovering and manufacturing chemicals. In the process, zinc and hemicellulose are recovered, the use of alkali is intensified, sodium sulphate is produced by efficient crystallization, and wastewater is run through a biological treatment plant. As a new raw material for viscose fibers, soluble pulp made from recycled cotton products by the cellulose depolymerization process (Re:Newcell Ltd, alkali + oxidation) has been used together with wood-based soluble pulp, which reduces CO2 emissions and reduces the carbon footprint.

Enzyme technology in fiber production: Biocelsol

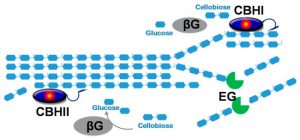

The Biocelsol technology was invented in the late 1980s at Säteri Fibres. Alkali-soluble cellulose was obtained by treatment of dissolving pulp with Aspergillus and Trichoderma enzymes together with mechanical pretreatment (Fig. 4).

Figure 4. The mechanisms of action of enzymes in activation and degradation of cellulose: endoglucanase (EG) affects separation of molecular chains and improves the penetration of sodium ion. ( A. Singh et al., Biofuel Res. J., 4(2):600-610)

The fiber spinning technology was developed in several projects, in particular in the EU NMT funding (Biocelsol) in 2004-2007 and in the Fibic/Tekes program in 2009-2013. The goal has been to make viscose-level fiber by modifying existing unit processes. The programs have also used very thick and viscous solutions as well as the so-called kneading processes. In this case, the production of textile fibers is linked to the pulp mill production, so that the raw material can be transported properly treated and “never dry” directly to the beginning of the water-based process. The EU-wide cooperation in the NeoCel project in 2017-2020 has led to a joint pilot plant project between TreeToTextile (Re: NewCell) and Stora Enso in Sweden in the amount of 1,500 t/a. Stora Enso has also applied for an environmental permit for a similar mill for the Uimaharju mill in Finland, however due to the market situation the production of dissolving pulp was stopped in early spring 2021. In case EU SUP Directive causes limitations for conditions that facilitate viscose technology, e.g. by regarding viscose fibers in the “not chemically modified” category, Lyocell, Ioncell and Biocelsol technologies offer better alternatives to increase interest in more environmentally friendly regenerated cellulose fibers.

Figure 5. The comparison of CS2-based viscose (left) and enzyme-based Biocelsol process.

Modified alkaline process: spinning into alkaline bath and additives

Tree To Textile Ltd, owned by Stora-Enso, H&M, Ikea and LSCS Invest, has developed an application of chemo-mechanical activation method for the pulp fibre. Cellulose-containing composition is produced by injecting an aqueous alkaline spindope solution or suspension into alkaline spinning bath. According to patents of the company, cellulose slurry comprises a cold aqueous sodium hydroxide solution, finely dispersed nanofiller additive and activated cellulose. The spin dope comprises of sodium hydroxide 6-9% by weight and a cellulose content of 5% by weight or more and a nanofiller additive content of from about 0.1% to 10% by weight calculated on the cellulose. The spin dope may be manufactured by any known procedure by the art of dissolving cellulose into cold alkali. Cellulose concentration is from about 5% to about 12% by weight of spin dope and at least one of additive and a nano-sized structured particulate filler resulting in wet tensile strength of greater than about 10 – 15 cN/dtex.

Additive and/or nanofiller in total is present in the range from 0.1-10% by weight calculated on the cellulose and having been in contacted with the cellulose spinning dope with an aqueous coagulation bath fluid preferably having a pH value above 7.

The spinning bath is diluted sodium hydroxide (concentration lower than in the spin dope) kept at a temperature of about 10-40°C and coagulation liquid optionally containing a dissolved salt, an aluminium compound, a magnesium compound and/or sodium carbonate or sodium sulphate. The coagulation bath may also consist of organic alcohol or ketone alone or combined with salt. The spinning dope is regenerated by using evaporation based on the different solubility of sodium carbonate, zinc carbonate, and other carbonates.

The polymer additives are used to improve the mechanical properties and elongation of the fiber. Typically, the polymers are present in an amount of from about 0.1% to about 10%, the remainder being cellulose or derivatised cellulose and optionally minor quantities of other additives such as urea, zinc, and other ingredients. Suitable polymer additives are alkali soluble adduct of PP, PE, PMMA, and acid substituted vinyl polymers, such as ethylene acrylic acid (Primacor by Dow), PAA-co-AA, functionalized polyethers and polyesters and polyolefine carboxylic acids and combinations.

The optional materials may be used to modify the processability and/or to modify physical properties such as elasticity, tensile strength, module, and other functional properties of the final product. The wet tensile strength of cellulosic fibres can be significantly enhanced by the addition of certain nano sized particles to the spin dope forming a composite cellulosic fibre upon coagulation of the spin dope. Halloysite or carbon nanotubes are examples of inorganic nanofillers that can be added to the alkaline spin dope.

Lyocell

The production of Lyocell fibers based on carbon-positive NMMO technology is currently about 500 kt/a and due to the investment decision of Sateri it is reaching 1500 kt/a by 2025 Its initial problems with explosions and fiber quality problems, have been able to control by the crosslinking, production stabilizers, control and using cross-linking chemicals. Due to the NMMO process and the high cost of the solvent, more than 99% yield is evitable in recycling process (Figure 5). The latest investment in Lyocell fibers (Lenzing) will be completed in 2023 in Thailand and will be 100 kt / a. If the current other four manufacturers continue to increase their production capacity by 50 kt / a every five years, we will get by 2050, additional capacity of 1.0 million tonnes / year, ie a total of 2.5 million tonnes / year in 2050.

Figure 6. The process scheme of lyocell fibers (Aalto University)

Ionic liquids

IonCell’s “dry-jet-wet” technology is an ionic liquid dissolution method that provides fibers very similar to those of NMMO. It has the advantage of a wider range of raw materials, e.g. recycled cotton and the use of field pulp and higher fiber strength, but with the disadvantage of more difficult solvent recycling. There is one pilot plant in the world (Metsä, Äänekoski) for demonstration, which produces fiber 500 tons per year. It is likely that factory-scale production could start at 10-20 times volume if it seems profitable. Even higher capacity (50 kt / a) would be possible in Finland, when the integration into pulp production at the Biorefinery could be implemented. The success depends on profitability and market and most of the plants, estimated at 3, could be built in Japan and elsewhere relevant by 2050. IonCell products have the potential to compete with traditional Lyocell and as a co-product for objects requiring special strength. The use of

Lyocell has increased in fiber blends with other bio-based man-made fibers and as reinforcement fibers in composites.

Pulp microfiber yarn

High concentration (20% consistency) aqueous dispersion (MFC) of pulp fibers and micro-fibrillated cellulose is produced directly without a dissolving step by means of a method developed by Spinnova (Figure 7). A gel becomes a strong wire after drying from the mixture of micro/nanocellulose, eutectic solvent (choline chloride) and rheology modifiers flowed in a special nozzle causing turbulent movement. In this case, the binding between the cellulose molecules is increased by its flow orientation, rheology modifiers and choline chloride. The yarn is made water resistant by adding polymer to the gel binder, polyacrylic acid (PAA) maximum 25%. Many can be used in the manufacture of fibrous yarn alternative sources of cellulose, e.g., soluble cellulose, paper pulp, and cereal straw.

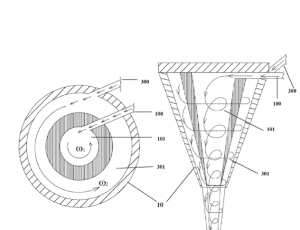

The capacity of the pilot plant in Jyväskylä is 100 t/a, and the resulting logical industrial pilot could be 1000 t/a. The process requires the integration of MFS or nanocellulose production into yarn production and to save on transportation costs. Needed for higher capacity, eg 100 kt/a the number of spinning nozzles is high but can be solved by using a rotary nozzle in addition textile yarn spinning techniques (Figure 6). The product segments to be retrieved determine the required thread number, e.g. T-shirt 20-30 tex and Denim jeans 100 tex. Particularly crucial to future demand are the product properties compared to other cellulosic fibers, such as strength, wet strength, elasticity, flexural stiffness, friction properties (feel), dyeability of the fabric, duration of repeated washes, ecology and price. The use of synthetic binder polymers should be carefully considered regulated by the European Single-Used Plastics Directive (SUP), and possible marine pollution effects.

Figure 7. Formation of a (nano)cellulose-polymer-composite yarn from a water-surfactant mixture in a rotary nozzle (upper view and side view).

Recycled cotton as a raw material for carbamate fiber

Cellulose fibers regenerated through a solution of cellulose carbamate can be made from recycled cotton cellulose and urea. After synthetizing cellulose carbamate, the fiber spinning takes place into acidic bath by process similar to viscose . Cellulose carbamate is very stable material and could be stored months for transportation and spinning.

The degree of polymerization of cotton cellulose is still so high in the textile used that it can be used in the production of regenerated fibers. Recycled Indigo Denim cotton garments are torn, bleached, converted to cellulose carbamate by heating in the presence of urea and dissolved in sodium hydroxide and spun into recycled fibers. Infinited Fiber Co (IFC) was born as a spin-off of VTT and established a 500-ton pre-commercial plant in Valkeakoski and will be soon invest 220 mill.€ for a factory of 30 kt/a production in Finland. One of the company’s investors is Royal Golden Eagle (RGE), which also owns Sateri Internatinal PTE, which bought Valkeakoski Säteri factory, is today the world’s largest producer of viscose fibers and wants to develop environmentally friendly and recycled raw materials. IFC technology also entered the related 10-year development project. The potential best raw material is obtained from products with high cotton content, of which T-shirts and Denim jeans are the largest individual, estimated at 2 million t/a. In addition to these, other raw materials can also be used, such as recycled paper fiber. Regarding fiber blends, the development of separation methods is key, for which IFC has its own proprietary technology. In early 2021, the company launched the fiber under the name InfinnaTM. By 2050, there could be 2-3 larger (100 kt / a) plants in the world, in addition to the Finnish test pilot, mainly in Asia (Sateri), but also in Europe, where clothing consumption is at a high level and recycling is being developed.

Recycled cotton textiles are purified and depolymerized (e.g., Södra and Re: Newcell) to be a raw material for a viscose process similar to dissolving pulp. Recycled cotton is also used as a raw material for lyocell fibers (Refibra / Lenzing).

Cellulose Acetate

Cellulose acetate and triacetate fibers have remained on the market, at a level of 0.7 mil.t / a due to good silky properties. Cottonseed linters and high molecular weight soluble cellulose are used as raw materials. Compared to other polymeric materials cellulose acetate and triacetate textile fibers are luxuriously felt in clothing products. Applications include relatively low strength filaments, mainly light underwear and lining fabrics, and staple fiber cigarette filters. Fabrics made from them have an excellent feel, dyeability and gloss. As films and coatings, cellulose acetate and triacetate work well and are very clear.

Combining the ecological properties of cellulose acetate with technical and bio-based man-made fibers (eg PA) in textile products as a whole provides an environmentally friendly alternative to plastic-type products. It is can be assumed that with cellulose and acetic acid being bio-based products, there will also be a clear increase in cellulose acetate production, up to 1.5 mill.t / a over the next 30 years.

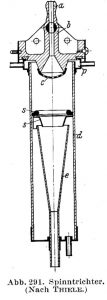

Cupro

Kupro fibers have developed into marginal special filament fibers such as natural silk (150 kt/a) due to their good use properties. Production growth has been limited by the spinning method, in which yarn filaments are stretched with water in a spinning funnel. Spinning is usually performed by pulling the fibers past the nozzle with flowing water and stretching in the gel space occurs in the tapered portion of the funnel in the regeneration bath as a result of the increasing flow rate. The spin speed is up to 150 m / min.

In Japan, funnel spinning has been developed by combining several successive goagulation, and stretching baths, and new methods are claimed to reach spinning speeds in excess of 800 m/min. After spinning fibers are passed to a sulfuric acid copper removal bath and rinsed several times before drying. The recovery of copper from the used spinning bath is done by ion exchange technology, which can recover up to 99%. 40-50% of the ammonia can also be recovered by evaporation in a spinning bath.

Figure 8. The design of a funnel-spinneret used in cupro spinning (Götze, Chemiefasern nach viskoseverfahren)

Figure 8. The design of a funnel-spinneret used in cupro spinning (Götze, Chemiefasern nach viskoseverfahren)

Bacterial cellulose

Cellulose is the basic material of trees and other plants and is also produced by bacteria such as the genera Acetobacter, Sarcina ventriculi and Agrobacterium. The fibers produced by the bacteria are nanocellulose and a technology has been developed to produce them, where they are grown on the surface of the reactor water. Fibers can be mechanically separated from the surface layer of the reactor. Bacterial or microbial cellulose has different properties than vegetable cellulose and is characterized by high purity, strength, formability and increased water holding capacity. Such microbial cellulose (MC) is a material suitable for medical products, nonwovens and absorbent hygiene products (nanollose).

Birity Cellulose of the Aditya Birla Group, one of the world’s largest manufacturers of viscose and lyocell fibers, announced a patent partnership with Nanollonen. The title of the patent application is “High-strength lyocell fiber for bacterial cellulose and its manufacturing process” and is a significant step forward compared to Nanollonen’s previous bacterial cellulose products Nullarbor ™ and Nufolium ™.

Using the Lyla cell process, a group of fiber experts from the Birla Cellulose, Pulp and Fiber Innovation Center has produced Nullarbor fiber that is finer than silk and significantly stronger than traditional lyocell made from soluble pulp. This lyocell fiber is made using a closed-loop process with low water and chemical consumption, as well as waste generation. Nullarbor ™ lyocell fibers are produced using organic waste from industry and agriculture as raw materials.

The companies also emphasize “Nanollose’s Tree-Free Cellulose” as a fiber raw material that makes it possible to obtain one of the most environmentally friendly and durable fibers.

Carbon fiber

Carbon fibers are produced by heat treating high-carbon containing materials, which means low weight losses in pyrolysis, such as PAN, pitch, phenolic resins, and aromatic polyamides. High-strength viscose (polynosic, modal, lyocell) is the most widely used bio-based raw material. Although the carbon content of viscose cellulose is quite high, 55%, the yield (11-15%) is still low due to pyrolysis mechanisms.

Thomas Edison first used cellulose fiber in the 1880s when he invented the carbon fiber filament of a lamp from cotton. National Carbon and Thornel produced carbon fiber from high-strength polynose-based fiber until the 1960s using high-temperature graphitization. Due to the cost of the hot stretching process, the low yield, and the mechanical properties, the production of these fibers was stopped.

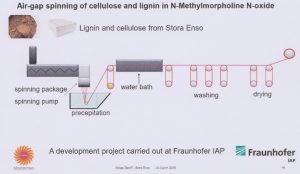

In a development project of Fraunhofer Institute, cellulose is converted to viscose or dissolved in organic solvents and mixed with a solution of lignin, which is spun into a precursor, which in turn is thermally treated to carbon fiber. Lignin is sold as a granular product that is easier to use as a source of biochar in energy storage systems, such as electric vehicle batteries, as bio-based binders in plywood, and as a carbon fiber material.

Figure 9. The process scheme of spinning cellulose/lignin blend for a carbon fiber precursor.

Stora-Enso in 2021, a pilot plant will be built on the Sunila mill site, where bio-based carbon material will be produced from lignin separated from softwood pulp. It can be used to make batteries used in electric cars, consumer electronics and large energy storage systems, for example