The 4rd Cellulose Fibre Conference in Cologne: Cellulose MM-fibers growth estimated 13 mill. tons by 2030

Production of Man-Made cellulose fibers

The 4rd Cellulose Fibre Conference in Cologne was secondly organised during Covid19 restricted conditions. It didn´t limit the number of participation due to interesting program covering sustainability, recycling, and alternative feedstocks as well as latest development in pulp, cellulose fibres, and textiles. Some new technical application areas of non-woven, packaging and composites were discussed, as well. With increased production dominated by viscose, capacities of more than 7 million tonnes of cellulose fibre products are expanding in technical hygiene and textiles. Due to their possibilities to reach extra high tensile properties, alternatives for carbon fibres for light-weight applications are under development.

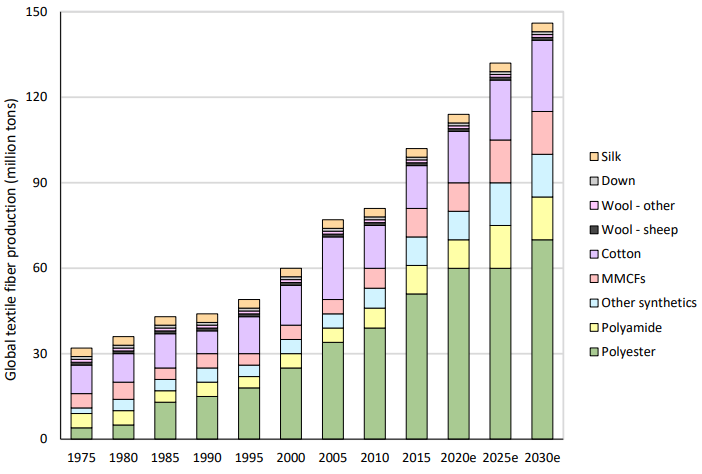

The textile industry is remaining a growth model despite of the current slowing of economics boosted by Russian-generated war in Europe. Additional fiber demand of 22 million tons is expected until 2025. The Fiber Year Consulting Group assumes that viscose, especially lyocell fibers will continue to outperform the market having potential demand of 4-5 million tons of new market by 2025. Growing awareness of need for sustainable clothing stimulates viscose fiber growth.

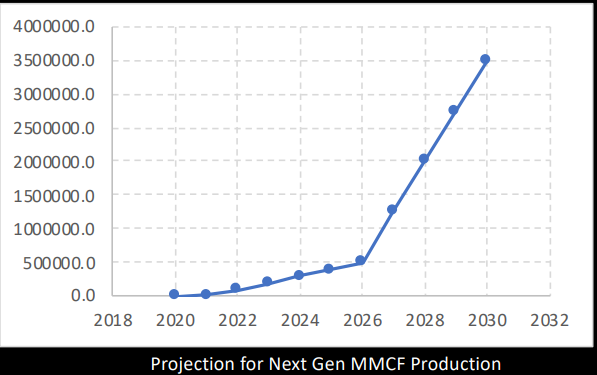

The estimation of Textil2Fashion is expecting that the MMCF market will grow from 7.2 million tons to 14.16 million tons within 9 years at CAGR of 7.8 per cent. Regenerated cellulose fibres possess beneficial characteristics from both synthetic and natural fibres. They have uniform mechanical and physical properties as synthetic fibres. Similarly, they are biodegradable, CO2 neutral, and have a low density as natural fibres.

According to Dr. Hassi from Scitech of Finland states that customers of fiber suppliers now have recycling, sustainability, and transparency at the top of both their strategic and operative agendas. The fashion value chain has transformed into active, networks with initiatives and development projects with objectives needed to meet the targets in time. Active players in MMCF industry can certainly strengthen their competitive position and their products can gain market share. Forest based MMCF’s existing integration with the global carbon cycle is to be better recognized to take full, justified benefit of their recyclability.

The estimated 166 mill. tons textile fiber consumption in 2030 is based mainly on the growth of PET production, however, pushes up regenerated cellulose up to 8% of total, which makes 13 mill. tons.

Carbon fibers from cellulose

Cellulose as the raw material for carbon fibers has been studied since Edison, who used cotton yarns as the conductive fibers in electrical vacuum class bulb lamps for lightning. Problems with cellulose-based carbon fibers generate from orientation of starting polymer, and low carbon and high oxygen content resulting in complex pyrolyzing chemistry. As the result, yields of carbon fibers and their properties are much lower compared to pitch and polyacrylonitrile.

The Denkendorf research team (Vocht, Ota, Hermanutz, Buchmeiser) at DITF receives the award in Cellulose3 Conference for the development of carbon fibers from cellulose. The process uses an ionic liquid solvent for wood and non-wood cellulosic materials for manufacturing carbon fibers with adaptable fiber properties. The oriented cellulose fibers are suitable in formation of the high tenacity carbon fiber structure at 1400°C using continuous lab scale processing at high carbon yield.The invention may result in manifold applications in composite technology, which is applied in aerospace, transportation, sports, and car industries all over the world. Lyocell-filaments from wood as precursor for carbon fibers were further studied Michael Hummel, Mikaela Trogen in Aalto university Helsinki. The alternatives are spinning and carbonization of high-quality cellulose fibers from high quality pulp and production of wood-based CFs with medium mechanical properties.

Cellulose and lignin can create a bi-component precursor fiber with high orientation of both polymers. Inge Schlapp-Hackl from Aalto University`s team explained, that using various types of lignin and considering molecular compatibility heterogeneous fiber structure is avoided. Enhanced carbon yield and mechanical properties possible and we need to Improve continuous carbonization to increase tensile strength further.

Nonwoven production technologies with pulp

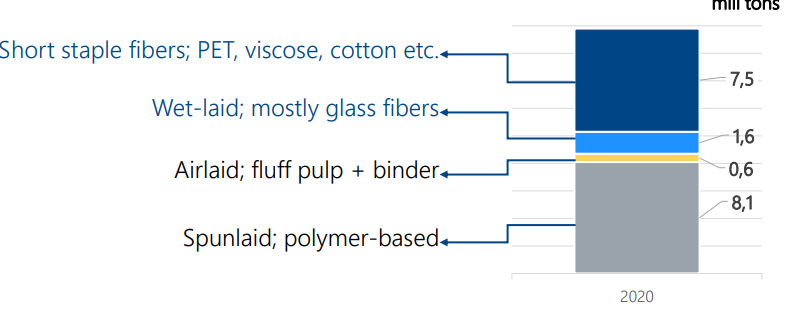

Amid the growth of nonwovens production reaching 18 mill tons cellulose fibers for sustainable product as increasing their share. Single-use nonwovens (such as wipes) are becoming more and more popular. Their main production technologies based on spunlace (hydroentangling), and needle-punching is often using the classic material mix polyester, and viscose. Air laid technology allows the use fluff pulp with binder as reinforcing the structure. Glass fibers and short staple viscose fibers are used in wet-laid process combined with binder.

Production technologies

Future opportunities and challenges, presented by Afry, for novel textile fibres basing on the increased demand powered by increased share of middle-class consumers. Present production of 115 mill. tonnes could be increased during some decade future up to 150-200 mill. tonnes. It consists of viscose and lyocell fibres made from dissolving pulp, polyester and recycled rPET from packaging’s waste, paper pulp using MFC process, and of residues of agricultural materials. In case recycled textiles building the logistics and infrastructure needs to be further developed. Recycled cotton and viscose textiles will be used as such and as a component for production of r-cellulose fibres.

MFC is using cheaper paper pulp in the value chain, but hemicellulose can pose problems. Sappi´s Stijfs was highlighting MFC´s importance in phasing out (micro)plastics, while contributing to sustainable development and reducing synthetic ingredients overall. The potential is high in replacing present additives in rheology modifications, water retention, imparting lightweight strength and sustainable alternative to plastics.

Environmental issues, circular economy and biorefinery

System approaches

Viscose and lyocell textiles are biodegradable and show marine degradation within 1 month without any harmful degradation products in sea surface and se floor conditions. They also maintain or even improve performance in comparison to existing commercial fossil-based products. Lenzing has showed a solution for hydrophobic properties lyocell fibres – comparable to PET fibers – which is maintained after carded hydroentangling (spunlaced) processing.

Canopy, environmental not-for-profit service established 21 years ago. The activities have been focused on direct purchasing power and market leverage, support brands and retailers to embrace sustainability, seek systemic solutions to protect forests and biodiversity and climate- Up to 2021 total of 455 global brands committed to sustainability criteria and received green shirt designations. The companies’ combined revenue was US$791 billion. In 2021 about half of global production capacity, 13 MMCF producers have earned ’green shirt’ designations, and only two producers maintain ranking of ’dark green’ shirt. Many producers are testing, trialling, and/or prototyping with strong interest in China, and are commercially manufacturing MMCF with pre-and post-consumer waste cotton textile.

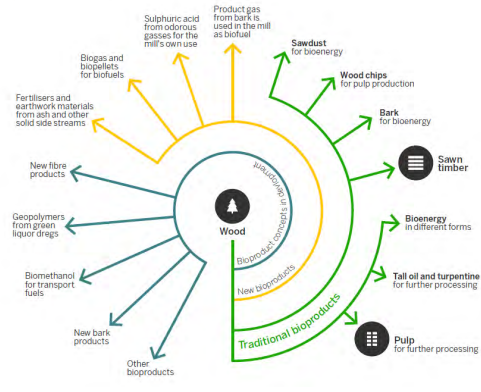

According to Metsä Biorefineries, systems allow highly efficient and cost-effective processing of biological feedstocks into a range of bio-based products and offer a platform for partnerships & collaboration. In many cases this happens in conjunction with the production of bioenergy. Optimization of the system, i.e., several material & energy streams parallelly and the whole is more than the sum of its parts. The multiple actors in the value chain should play as a team and optimize the ‘system’ together: in an ideal circular economy material, energy, value and information flows are optimized.

Important to recognize that from waste to product ‘Cascading in time’ and ‘Biorefinery’ are complementary concepts. Cascading in function is co-production, which can be achieved by using biorefinery. Co-production is the production of different functional streams from one biomass stream, maximizing total functional use. Traditional wood-based products consist of 7 products from wood biorefinery. New approaches include 8 additional products, mainly chemicals and a new pulp-based environmentally sound textile fiber.

The utilization of wood at Metsä Biorefineries in Finland.

Viscose and recycling cellulose

Lenzing, one of world top 3 producer of viscose and lyocell fibers, actively increases self-sufficiency for steam and heat production and increased utilization of biomass for energy production. Air purification plants produce steam that is converted into electricity and the necessary rest is bought from renewable grid energy. Biorefinery is used factories such as in pulp mill using cleaner pulp and producing side chemicals and in Lyocell process by recycling the solvent. Decreased steam demand and higher energy efficiency through capacity increase are achieved. For viscose process, an additional air purification plant reduces GHG emissions. Recycled cellulose from textile waste is used depending on availability and product properties.

The part of Indian conglomerate Aditya Birlas´Cellulose aims to net zero carbon emissions across all its operations by 2040 and achieve 50% reduction in its greenhouse gas emissions intensity by 2030. Birla cellulose targets to scale recycled fibres to 100,000 tons by 2024 and reduce sulfur release to air by 70% at all fibre sites with novel recovery units by the year 2022. Plans include the reduction in water intensity by 50% in VSF manufacturing by the year 2025. Th sustainability performance of key suppliers will be stressed by year 2025 including the use alternative feedstock such as of pre- and post-consumer waste into fibre.

Claesson and Weilach presented the common viscose/lyocell recycling project of Södra and Lenzing. The idea is to collect used cotton and PET/cotton textiles for purification and blending with dissolving pulp. The target is to produce 25 kt/a textiles capacity when recycled content in pulp is 50%. The development includes sorting and quality of raw materials, flexible processes, e.g. decolorization and handling of non-cellulosic, non-polyester contents (elastane, rubber). Similar type of project was presented by Crnoja-Cosic from Kelheim and Cavalli-Björkman from Renewcell, a Swedish cotton recycling project to produce viscose fibers. It has been developed over the course of a decade by researchers at KTH producing multiple global patents. The target of cooperation Renewcell and Kelheim is development of a large-scale production of high-quality viscose fibers from up to 10,000 tons per year of Renewcell’s 100% textile recycled row material Circulose®.

Circulose® is a dissolving pulp made from 100% textile waste, like worn-out jeans and production scraps. Kristina Elg Christoffersson from Renewcell, Sweden explained that worn-out jeans successfully used to make viscose staple fiber and filament. The company is aiming for lyocell, acetate and other types of man-made cellulosic fibres.

According to the presentation of Meister, hemp straw was conversed to high purity dissolving pulp grades for Lyocell fibre manufacturing and textile processing. An adjusted soda cooking process followed by additional pulp bleaching and washing steps for being compatible to the Lyocell process requirements. A laboratory scale NMMO process and prepared dopes exhibited satisfying properties for air-gap spinning producing Lyohemp fibres and filaments well sufficient mechanical properties for further textile processing.

Sebastiá was presenting the possibilities to utilize pulp mill processing in chemical recycling of textile waste. The idea is basing on the big share of cellulose material (cotton, viscose, lyocell, cotton/polyester, flax) for depolymerize and decrystallize for further treatments, e.g. enzymatic hydrolysis. Existing technology can be used in bleaching, pre-treatment with internal streams in the mill and energy integration. Thus, reduction of capital and operational costs as well as mitigate risks during scale-up. There are ongoing research project to explore sugar production from waste textiles with Lund University and RISE. Several chemicals are reported to be produced, e.g. 1.4-butanediol, caprolactam (from PA 6), furan derivatives and ethanol. Techno-economic studies to explore potential bottlenecks and risks are going on Industrial collaborations with partners along the value chain, both upstream and downstream.

Antje Ota and the team from DITF Denkendorf presented EU-financed HEREWEAR project developing Cellulose fibers from alternative feedstocks. The aim is to use of bio-based materials as well as reuse and recycle used materials of the textile sector. Project aims at the creation of a European ecosystem for locally produced circular textiles and clothing made from bio-based resources. DITF is responsible for the wet spinning of cellulosic filaments from bio-based waste streams and marine waste. Establishing the textile circular economy based on the DITF Digital Textile Micro factory structure for new local/regional circular sustainable spinning technology for cellulose filaments. The funding from 2020 to 2024 comes from a € 7 million budget with a consortium 6 research organization, 8 SMEs and 1 large enterprise from 9 different EU countries, 1 US.

Wayne Best from Nanollose ltd (Birla, India) compared bio-mass fermented bacterial cellulose with wood-based fibers. It does not require trees, wood-pulping process and hazardous chemicals or pesticides an can be procuced with reduced energy requirements. Because it uses natural fermentation process of agricultural wastes & by-products, it does not require arable land or even light. It is stronger than conventional lyocell made from wood pulp, as well.

The aim to reuse and recycle various bio-based materials as well used materials of the textile sector wa presented by Up-cycling of textile waste by means of Ioncell® presented by Dr. Inge Schlapp-Hackl Ioncell® Lyocell type dry jet wet spinning technique.

Viscose and novel cellulose fibers

Carlo Centonze of HeiQ reported that the global textile apparel market amounts to US$1,7 trillions in 2022 growing annually by 3.39%. The fashion industry is estimated to be responsible for 8-10% of all global greenhouse gas emissions according to the UN being between 3 to 3.5 billion tonnes of CO2 into the atmosphere every year Worldwide. Due to decreases the average number of times a garment is worn before disgarding and the per capita ownership of textiles, 26% of the global carbon emissions will be caused by 2050. HeiQ invests in pilot plant of 100 tons annual capacity of cellulose filaments in 2022 continuing a mass manufacturing plant up to 30’000 tons annual capacity in 2024. HeiQ AeoniQ is a continuous cellulosic filament yarn, which can be recycled eternally without loss of performance.

LIST technology, based on new type of kneading-extrusion machinery for CMMF innovations, has proved to be an essential part for developing high performance polymers into fibers. According to Manuel Steiner it suits for wide range of types of celluloses producing high quality for spinning solutions with higher capacity per line. Being robust and scalable, it can be utilized easily from lab to industrial projects

Dominik Mayer of Kelheim Fibers presented the functional fiber (CELLIANT®), which contains a blend of natural, thermo-reactive minerals of silicon dioxide and aluminium oxide. Aluminum oxide is the molecular foundation of the corundum family of gemstones and helps reflect energy. The functional fiber captures, converts and reflects heat back as infrared (IR) energy, which increases local circulation and cell oxygenation. Functional viscose, CELLIANT® is designated as a Class 1 Medical Device in Australia, Canada, the European Union, Japan, New Zealand and the United Kingdom. It is cleared to market in China, India, Indonesia, Korea, Mexico, Peru, Philippines, Russia, Singapore, Thailand, and Taiwan, with more countries and regions to follow

Kuperman and Natalio from Weizmann Institute reported studies on biologically fabricated cotton fibers with tailored properties. Growing fertilized cotton ovules in vitro were producing complex biomaterials with tailored properties usin biological system (cotton) plant physiology and biochemistry and transport mechanism.

New cellulose fiber products

Taina Kamppuri from VTT Finland showed results of chemical modifications, cationization and allylation, carried out to kraft pulps. Reaction efficiency of cationization and allylation reactions was found to be rather low, < 5 %, however substitution was kept low to avoid solubility in water and to achieve regeneration. Hemicelluloses, especially xylan, seem to be the more reactive compared to cellulose in the derivatization reactions. Reaction optimization and/or reaction conditions where hemicelluloses could be retained on the surface of modified fibres might solve the loss of hemicelluloses. Reactive groups were found to be stable during dissolution and regeneration. This opens up possibilities to post-treat the fibres to obtain different functionalities and improved technical, e.g. dyeing, properties.

Alkaline dissolution and spinning of cellulose textile fibers was presented by Åsa Östlund from TreeToTextile company, owned by Stora Enso, Ikea, H&M and LSCS Investments. According to results of pilot production of 350 kg/h the regenerated fiber has characteristics to replace both cotton and viscose. It has similar natural hand-feel as cotton and has comfort close to a cotton-linen blend. Washability is comparable and the fiber also brings a light viscose touch. It also borrows some of the luster, elongation and brilliance from viscose – while still fit for cotton replacement.

Nonwovens and special processes

Except of traditional multiple proven carded/spunlaced products from cellulose/PET fibers Germany´s Trütschler has developed carded/pulp technologies in cooperation with Voith Paper. Such are wet-laid/spunlaced) from paper-grade pulp and viscose/lyocell fibers carded/pulp from paper-grade pulp and viscose/lyocell fibers. Pulp-based nonwovens wetlaid-spunlace and carded pulp processes. First plants are already in service and the machinery has proven equipments and proven production processes as well as well-accepted final products for wiping applications.

According to Nina Graupner, University of Bremen, regenerated cellulose fibres have comparable mechanical properties to many types of natural fibres with a considerably higher toughness. They are well suited for applications requiring high impact resistance and completely degradable in combination with a biodegradable matrix. Research activities have increased significantly in recent years, however, there are only a few industrial applications in the composites sector. BFT company transforms raw bast fibres from hemp and flax plants to meet the exacting standards required by nonwoven customers. In the transition away from synthetics, natural fibres are vitally important to produce truly sustainable nonwovens, as well.

Demand for wood is accelerating as packaging, nonwovens, and textiles replace plastic with viscose and pulp. Deforestation is associated with biodiversity loss, soil erosion, increased GHG emissions, and climate change. Viscose simply replaces one problem with another. BFT allows nonwoven companies to accelerate sustainability goals and work towards a circular, zero waste future. Fibres are carefully individualized and standardized to meet converters requirements. BFT applies proprietary performance enhancements to the fibre to be more suitable for composites especially regarding uniformity of fiber length, and hydrophopbic adhesion properties.

Prasad Thitame from Nonwovens Birla presented options to plastic free spunlace, airlace and wet-laide nonwovens using bio-binders for feminine hygiene products. Major challenges with non-plastic materials are as follows:

- technologies like spun melt, thermal bonding, adhesive and embossing can use thermoplastic raw materials only

- there is not commercially available and proven bio alternative for SAP

- bio-based adhesives are still under development

- lower production efficiency with natural materials need development work

- consumers are used to dryness and performance delivered by engineered plastic materials

- consumers are used to thin pads, which is achieved through addition of SAP in core

Hydrophobic regenerated cellulose combines the advantages of natural & plastic/synthetics plastic/ materials in sanitary napkins. Commercially available viscose based top sheet for AHPs delivering the performance attributes. Viscose-based sanitary napkin (Purocel HP) top sheet passes the quality check of wetting and wetback required for performance.

Chemical compliance and hydrophobation of cellulosic textiles were presented by Anna-Stiina Jääskeläinen from Kemira Finland. The work has been motivated by sustainability development in textiles industry. Regulations and voluntary certificates are essential in chemistry development and commercialisation. Cellulose molecules are hydrophilic by nature; however, hydrophobic nature of fibres is an essential property for many textile products. AKD (alkyl ketene dimer), ASA (alkenyl succinic anhydride), rosin sizes are hydrophobation agents that are used for cellulosic products. Commercially available AKD fatty acids are mixtures of palmitic (C16) and stearic (C18) acids originating from vegetable oils. They are applied as water-based dispersions in neutral or alkaline conditions at a pH range around 6.5-10. Hydrophobation by AKD shows a 3 step mechanism, such as adsorption of AKD particle on cellulose surface, heat-induced melting and spreading and spreading and curing (”sizing”).

Grete Concept – EU-financed project

Grete Concept, developed in EU-financed project, basing on lyocell type of process was presented by Ali Harlin from VTT Finland. Raw material bleached hard wood kraft pulp BHKP from Eucalyptus is used as a novel ionic liquid solvent to produce fibers comparable with Asian Tencel. Solvent recycling with nano filtration and evaporation results in decreased water contents, which are typical with NMMO.

Cellulosic fibre production from paper grade pulp Daniel Egas as athe 2nd example of Grete Concept, developed in EU-financed project. The use IL as solvent is likely to improves the environmental and economic performance of producing man-made cellulosic fibers. The use of enzymes at pretreatment are not likely to affect the environmental and economic performance of producing man-made cellulosic fibers. The integration of the pulp mill allows a direct consumption of the pulp mill energy surplus which has an overall positive impact on the system’s environmental single score and specially over GWP fossil. On contras to the reference concept, showed a lower variable OPEX, as well as a similar CAPEX investment requirement (7% difference). The socio-economic value of CO2 emissions makes concept a more attractive investment.

Development of cellulose solvents with better properties ‒ Hydrolytically stable, non-toxic and efficent SB-ILs was presented by Eva Gazagnaire from Beta Tech Centre in Spain. Some examples of IL`s undergo phase-separation from water making the recycling of the SB-IL easy and straightforward. Some ’Failure SB-ILs’ of GRETE turned out to be interesting for something else. It showed that fractionation of different types of polymers with selective dissolution seems possible. Some solvents seems efficient for a range of polymers and regeneration to hybrid materials could be developed further.

As the next results GRETE project Paper-grade Pulp as Raw Material for regenerated cellulosic fibres in an ionic-liquid based process was reported by Jenni Rahikainen. Hemicellulose from paper grade pulp can be dissolved and regenerated into fibres in high yield using ionic liquid [mTBNH][OAc]. Regenerated fibres prepared of pulp with low and high hemicellulose content had similar mechanical properties. Enzymatic pretreatment resulted in inferior mechanical properties compared to acid pretreatment. Immunolabelling can be used to track spatial distribution of xylan in fibres, which showed that hemicelluloses are more enriched to the outer layers of regenerated fibre.